The Global Cement & Concrete Association-India (GCCA-India) and The Energy Research Institute (TERI), jointly and in consultation with different stakeholder groups and subject matter experts belonging to the construction industry, prepared a document on the ’Decarbonization Roadmap for the Indian Cement Sector Net-Zero CO 2 by 2070’. The roadmap, launched in March 2025, aligns with the Government of India’s commitment to net zero emissions by 2070 and with the interim target for 2047 in line with the vision of ’ Viksit Bharat’. The GCCA-India and TERI deserve applause for publishing the roadmap report. This article briefly describes the eight decarbonization levers envisaged in the roadmap. In the opinion of the current author, although the title of the roadmap and the discussions therein revolve around the cement sector, the cement end-user sectors such as concrete, walling materials, plasters, etc. also need to be included in the decarbonization roadmap. This is because the roadmap envisages maximum reductions in CO 2 emissions from the decarbonization levers of ’cement use efficiency’ and the ’use of SCMs’. The current author believes that the onus of reducing CO 2 emissions through cement use efficiency and SCM use mainly rests with the concrete and allied sectors. In the latter part of the article, the author briefly outlines the current and main future trends in the concrete and related sectors, and highlights that the adoption of material-efficient design and structural-efficient design, aided by optimization and digitization techniques, would go a long way in achieving the decarbonization goals, provided all stakeholders from the construction sector join hands together and gear up to achieve these goals.

* The article was initially published in the April-June 2025 issue of ICI Journal. The same is included here with kind permission from ICI for wider dissemination.

INTRODUCTION

The unprecedented rise in greenhouse gas (GHG) emissions is one of the major factors responsible for climate change that is causing an alarming increase in the occurrence of floods, cyclones, droughts, wildfires, heatwaves, rise in sea levels, etc. in different parts of the world. It is reported that during the period 2000 to 2019, there were 7,348 major recorded disaster events claiming 1.23 million lives, affecting 4.2 billion people and resulting in approximately US$ 2.97 trillion in global economic losses [1]. The 2015 Paris Agreement adopted by 196 countries was a turning point in the efforts to mitigate the adverse effects of climate change. A solemn commitment was made by these countries to keep the global temperature rise this century well below 2°C above the pre-industrial levels and pursuing efforts to limit the temperature increase even further to 1.5°C. Unfortunately, despite a variety of mitigative measures initiated in many countries, it is for the first time in the history of the Earth that the year 2024 witnessed the breaching of the global warming temperature by more than 1.5°C from the pre-industrial level. The recent UNEP report observes that the global GHG emissions are setting new records (57.4 GtCO 2e in 2022) and that the world is heading for a temperature rise far above the Paris Agreement goals [2].

The construction industry plays a significant role in global carbon emissions, contributing to environmental degradation and climate change. According to the latest report of Global Alliance of Building and Construction, the building and construction sectors account for 34 % of the total energy used globally and are responsible for 37% of carbon emissions [3]. Although similar India-specific data are not available, broad trend from urban India would generally be comparable.

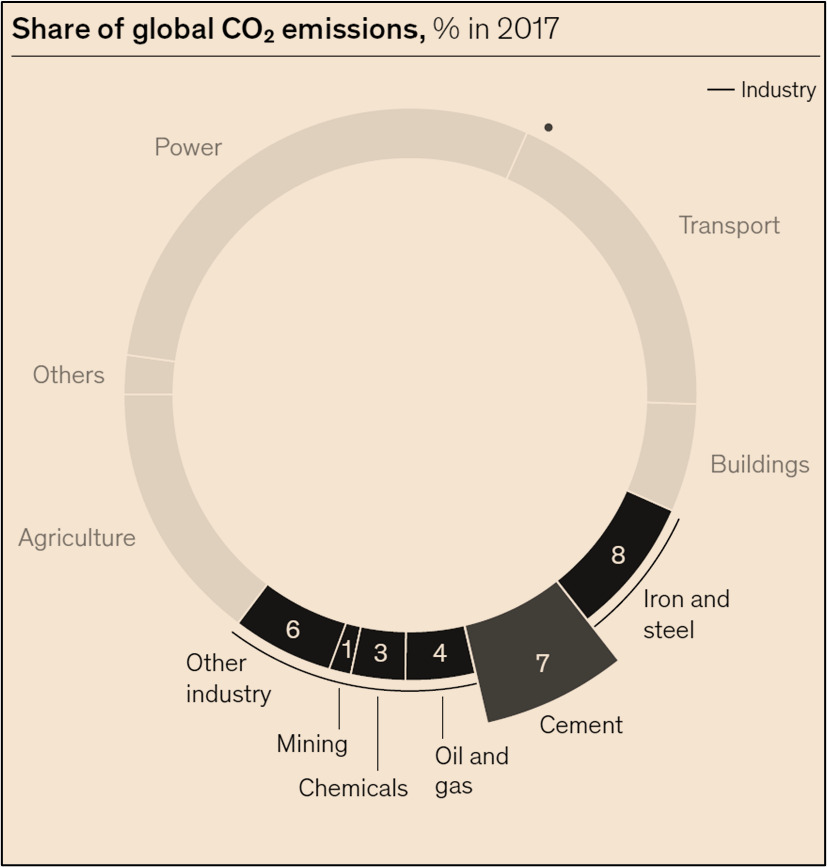

In the construction sphere, cement and steel happens to be the backbone of construction. Both these materials have been used the world over on a massive scale. While the use of cement has crossed more than 4 billion tonnes/annum, that of steel has exceeded 1.8 billion tonnes/annum. These materials are highly energy-intensive, requiring massive energy during their production which leads to substantial greenhouse gas emissions. While the cement sector alone accounts for nearly 7% of the carbon emissions globally, steel accounts for nearly 8% of the emissions, Fig 1 [4]. The global leaders of these sectors are fully aware of their responsibilities in the carbon emission domain and have already drawn plans and outlined pathways to achieve Net Zero emissions.

CEMENT SECTOR

Take for instance the cement sector. The Global Cement and Concrete Association (GCCA) which represents 80% of the global cement industry outside of China including some key Chinese manufacturers such as CNBM, West China, Taiwan Cement Corporation has been actively involved in developing the roadmap for net-zero emissions from the cement sector. The salient features of the roadmap are included in GCCA publication “Our Concrete Future” and the same can be downloaded from GCCA website [5]. This global roadmap document can serve as a broad guideline for different countries.

Fig 1 Cement sector accounts for 7% of the total global carbon emissions [4]

India is a developing country which is aspiring to become a developed economy by 2047. The requirements of India are different than those of the rest of the world. India needs massive development of its physical infrastructure involving construction of roads, bridges, highways, expressways, ports, harbours, metro rails on the one hand and residential and commercial housing in the urban and rural areas on the other. However, while undertaking the mammoth economic development, India also needs to ensure that such development is necessarily sustainable in nature.

Considering this, the leading cement companies in India under the banner of GCCA-India, decided to develop an India-specific roadmap for the indigenous cement and concrete sectors. GCCA-India constituted a Task Force with representatives from member companies and decided to invite subject matter experts in the Taks Force. The Energy Research Institute (TERI) was selected as a knowledge partner.

After detailed rounds of discussions with key stakeholders including leading architects, engineers, R&D institutions, academia and sectoral experts and after careful analysis of the decarbonization levers, TERI prepared a draft report on the roadmap which was thoroughly discussed and finalized. Due weightage has been given in the roadmap report to the cement industry’s objective of aligning its strategies with India’s net-zero 2070 target and nationally determined contributions, supported by enabling policy framework. The GCCA-India and TERI launched the roadmap for Net Zero CO 2 emission by 2070 for the Indian cement sector in March 2025 [6], Fig 2. This roadmap aligns with the Government of India’s commitment to net-zero emissions by 2070 and the interim target for 2047 in

Fig 2. Decarbonization Roadmap for the Indian Cement Sector [6]

line with the vision of ‘Viksit Bharat’. The present author would like to congratulate the GCCA-India and TERI for conducting the exercise of evaluating futuristic societal need of cement and then formulating the roadmap for achieving carbon neutrality associated with the use of cement.

CEMENT DEMAND PROJECTIONS

The Indian cement industry is currently experiencing healthy growth, on account of rapid urbanization and increasing demand for housing and infrastructure requirements. The urbanization trend is bound to get strengthened further in the near future. As estimated by the International Energy Agency (IEA), additional 270 million people are expected to get added to India’s urban population from 2020 to 2040, requiring an extra 30 billion m 2 of residential floor space by 2040 [6]!.

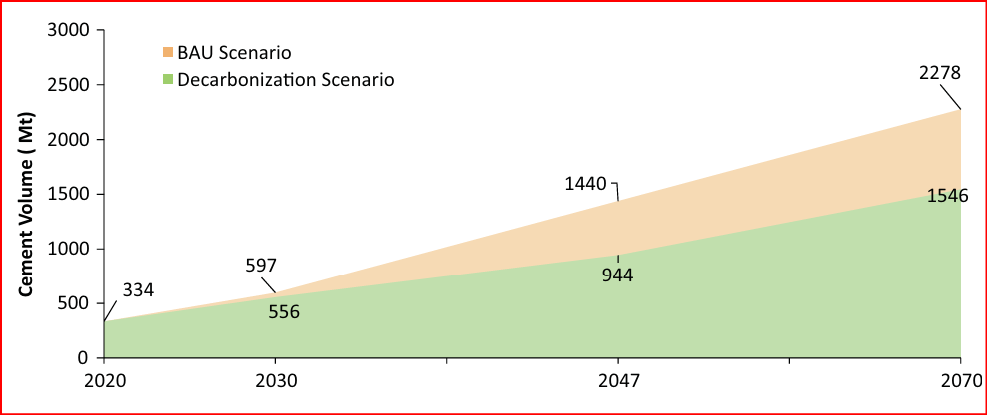

Predicting long-term growth is indeed a difficult task in view of the uncertainties in the socio-economic factors. The roadmap report assumes an optimistic CAGR to meet the growing cement demand — both under Business as Usual (BAU) and Decarbonization Scenario. The CAGR varies from 6% during 2020-30, 4.5% during 2030-47 and 2.3% during 2047-70. These growth rates correspond to a cement production of 597million tonnes in 2030, 1440 million tonnes in 2047 and 2278 million tonnes in 2070, Fig 3. The report assumes that while the growth in cement demand would be happening, there would also be an improvement in the ‘cement use efficiency’ (owing mainly to the increase in awareness of sustainability principles amongst the end users). Its effects would start showing results with effect from 2030 onwards. Accordingly, the cement demand would get reduced to 556 million tonnes in 2030, 944 million tonnes in 2047 and 1546 million tonnes in 2070 as shown in Fig 3 (shown the green colour).

Fig 3. Cement demand projection from 2020 to 2070 [6]

DECARBONIZATION LEVERS

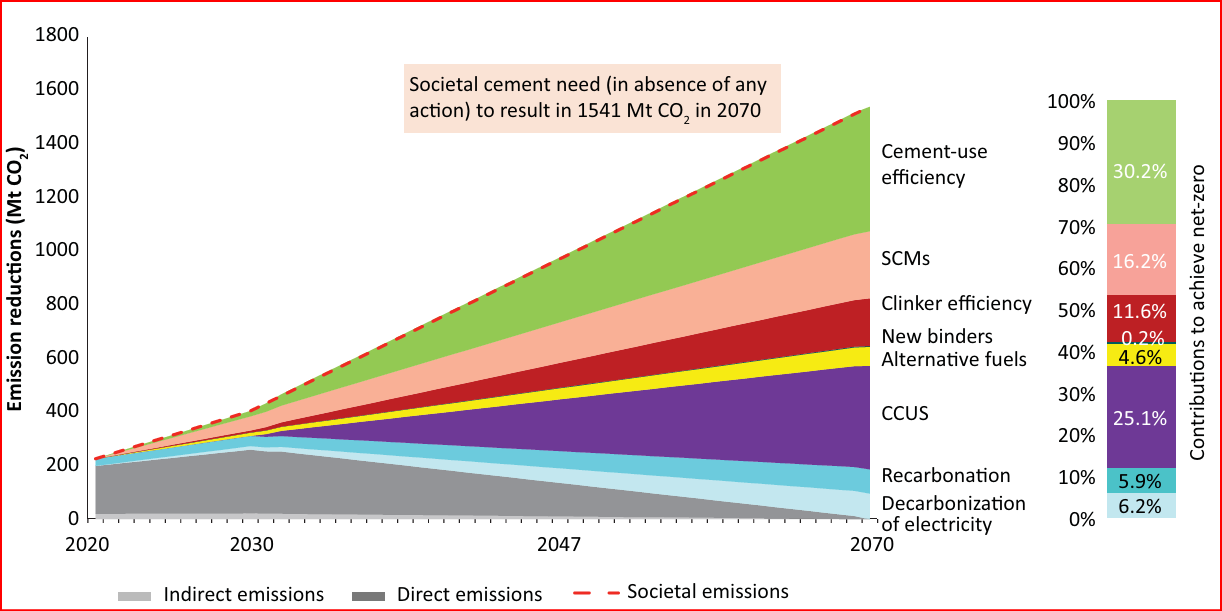

The roadmap report identifies the following eight decarbonization levers to achieve net-zero emissions by 2070. The figures in the bracket indicate each lever’s contribution to achieve net-zero. The same details are shown graphically in Fig 4.

- Clinker Efficiency ( 11.2%)

- Use of Alternative Fuels ( 4.6%)

- Increased use of Supplementary Cementitious Materials (SCMs) ( 16.2%)

- Decarbonization of Electricity ( 6.2%)

- New Binders ( 0.2%)

- Carbon Capture, Utilization and Storage (CCUS) ( 25.1%)

- Re-carbonation ( 5.9%)

- Cement Use Efficiency ( 30.2%)

Fig 4. Net zero pathway for the Indian Cement Sector [6]

The following paragraphs throw more light on some key levers which can have the ability to reduce CO 2 emissions on a larger scale.

Clinker Efficiency

An overwhelming majority of cement produced in India is through the energy-efficient ‘dry process’ technology. Yet, there is a scope to improve the energy efficiency further. This could be achieved by increasing the share of biomass as fuel to the maximum extent possible. At a later stage, the roadmap document suggests that the adoption of advanced technologies such as green hydrogen, kiln electrification, solar thermal will go a long way in improving the energy efficiency in cement production.

Alternative Fuels

The Indian Cement industry is already exploring the economic viability of using of alternative fuels with biogenic content such as municipal solid waste, plastic waste, used tyres and industrial waste for thermal substitution of fossil fuels. The roadmap document envisages that the share of fossil fuel wastes would reach to 35% of the total fuels used by 2070.

Supplementary Cementitious Materials (SCMs)

It is well known that the use of Supplementary Cementitious Materials (SCMs) in cement and concrete helps in reducing the carbon emissions of construction. As far as cement is concerned, fly ash- based Portland Pozzolana Cement (PPC) and GGBS (ground granulated blast-furnace slag)-based Portland Slag Cement (PSC) are quite popular and accounted for nearly 73% of the total cement produced in India during 2020-21. Considering the increasing need for cement in the future, three new varieties of blended cements are getting added in the cement portfolio. These include Portland Composite Cement (clinker 45%, fly ash 15-35%, GGBS: 20-50%), Limestone Calcined clay Cement (LC3) (clinker 35%, calcined clay 30%, limestone 15% and gypsum 5%) and Portland Limestone Cement (Limestone addition 5-15%)

Apprehensions are expressed in certain quarters about the availability fly ash and GGBS in years to come. In spite of government’s emphasis on increasing the renewable energy capacities in the country, experts tend to believe that coal would continue to be the mainstay of energy, accounting nearly 45-50% share in India’s commercial energy mix by 2030 and beyond [8]. The roadmap report assumes that fly ash generation would continue up 2047 and perhaps even beyond with a few coal-based plants operating with CCUS.

As regards GGBS, the National Steel Policy 2017 projected that the crude steel production would reach to 255 million tonnes by 2030, of which 153 million tonnes would be through the Blast-Furnace Basic Oxygen Furnace (BF-BOF). The Green Steel Report published by the Ministry of Steel highlights that the Indian steel industry is constrained to use coal-based blast furnaces and rotary kilns for steelmaking due to a lack of affordable alternatives [9]. Hence, GGBS would continue to be available for the use in cement (PSC) and concrete.

The projections on the obtainability of fly ash and GGBS up to 2047 and beyond ensure that blended cements like PPC, PSC, and Composite cements would continue to be available for the construction industry. The roadmap report estimates that by 2070 the fly ash demand for PPC and Composite cement would rise to 295 million tonnes, GGBS to 134 million tonnes and calcined clay (for LC3) to 110 million tonnes. These demands would hopefully be satisfied.

At present there are code-imposed limitations on the percentage replacement of clinker by the supplementary cementitious materials. However, once the practice of adopting performance-based specifications for concrete takes roots in India, it would open doors to the higher percentage replacement of OPC by SCMs; for example, say high-volume fly ash concrete permitting up to 50% replacement OPC by fly ash and high-GGBS concrete, allowing up to 70% replacement of OPC by GGBS. The roadmap report expects that as the share of SCMs in cement and concrete goes up, the clinker factor would come down from the present level of 0.75 to 0.56 by 2070.

Carbon Capture, Utilization and Storage (CCUS)

Carbon Capture, Utilization and Storage (CCUS) is considered as one of the promising technologies to reduce the process emissions in the cement plants. It is one of the crucial levers to achieve net zero CO 2 emissions. CCUS technology is presently in the nascent stage of development. Globally, only a few leading companies have initiated practical applications. However, CCUS is rapidly increasing in scale and sophistication.

In India, CCUS technology is not implemented by any cement company so far. Before undertaking any CCUS project, it is essential to plan, develop and establish suitable CO 2 transport and storage infrastructure. The NITI Aayog recommends development of ‘CCUS clusters’ and options to produce low-carbon downstream products. For this purpose, necessary regulatory and financial support would be needed from the government authorities.

The roadmap report observes that CCUS technology would play a significant role in India. However, it predicts that it will take time for India to tap this technology, may be by the middle of this century. The report predicts that by 2070 the adoption of CCUS technology would be able to reduce the CO 2 emissions from the cement industry by nearly 25%.

Nature-based Solutions

The roadmap document considers nature-based solutions (NbS) as an additional or complimentary lever along with CCUS that can supplement in capturing carbon. India has already committed to creating an additional carbon sink of 2.5 to 3 billion tonnes of CO 2 equivalent through additional forests and tree cover by 2030. The roadmap document suggests that limestone clusters and degraded forest can be allocated to the cement sector for energy plantation which, besides providing large volume of biomass for sustainable energy production, will also help in creating livelihood opportunities. The roadmap does not indicate the potential carbon reduction through this route as this is considered as an additional lever.

New Binders

Historically, efforts have been made in developing alternative binders such as reactive belite-based Portland cement, calcium sulpho-aluminate cement, magnesium silicate cement, alkali-activated binders, geopolymers, etc. Active efforts are still being pursued in developing and promoting the use of such binders. Simultaneously, considerable efforts are also being made in developing a new class of binders.

While the roadmap document envisages that the CO 2 reduction potential of the new binders would merely be 0.2% in the near future, it also recognizes that the ongoing R&D work being undertaken in different parts of the world may result in a breakthrough leading to the development of cost-effective binders (and SCMs) which would significantly alter the net-zero pathways.

Cement Use Efficiency

The roadmap document visualizes that there exists a vast scope to improve the cement use efficiency in different end-use segments. In fact, it envisages the highest CO 2 reduction - a whopping 30.2% - from this category. However, the document is silent on providing an elaboration on how the same could be achieved. Possibly, this could have been out of the scope of the document.

In the opinion of the current author, cement use efficiency not only includes driving economy in the quantity of the cement used but also improving its effective use. In the context of carbon emissions, this would also encompass ensuring reduction in the embodied carbon emissions from the concrete/mortar/plaster containing cement.

CURRENT AND FUTURE TRENDS

Here, the present author would like to provide a brief glimpse of the current as well as the possible future trends in India’s concrete and its related sectors. Hopefully, such discussion could be helpful in throwing more light on understanding the potential of the decarbonization lever of cement use efficiency.

Currently, a steep decline is seen in the prevalent labor-intensive technique of using site-mixed concrete. This age-old practice is getting replaced with ready-mixed concrete (RMC) and precast concrete. During the past decade, while the commercial RMC sector witnessed remarkable growth, spreading its wings in tier II and III cities, precast concrete plants producing non-structural elements - walling units (mainly AAC blocks), interlocking blocks, cover blocks, etc. - have also witnessed healthy growth. However, the spread of precast concrete plants producing structural elements has remained confined to captive, project-based areas. There are certain barriers to the growth of commercial precast plants selling pre-fabricated structural elements. These barriers may be overcome in the foreseeable future. Incidentally, the use of ready-mixed plasters are increasing.

Broadly speaking, the trends in growth of RMC and precast concrete/plasters are expected to get strengthened further in the near future.

In the opinion of the present author, major responsibility of implementing the cement use efficiency lever will fall on the shoulders of RMC and precast concrete sectors, the latter including the precast walling materials and ready-mixed plaster sectors too.

HOW TO ECONOMIZE USE OF CEMENT?

It is well known that the adoption of both RMC and precast concrete/plaster not only reduces the wastage of cement but also permits blending of varieties of SCMs in concrete, thereby reducing the use of ordinary Portland cement. However, since the RMC and precast concrete sectors are in their initial stage of development, the average blending of SCMs in the RMC and precast concrete has yet to reach the code-specified upper limits. The current construction practices provide excessive emphasis on compressive strength, with little attention to durability of concrete. It is well known that one of the basic parameters needed to achieve durability of concrete is the incorporation of an adequate amount of reactive SCM(s) in the mix (besides of course the use of low water/binder ratio) to achieve impermeable concrete. The awareness about the need to have durable concrete is growing and as it grows, the use of SCMs is bound to grow, reducing the cement contents in concrete. Incidentally, the mechanization and automation features in the RMC and precast concrete techniques will lead to improved controls over the quality of concrete, thus improving its long-term durability and hence sustainability.

HOW TO REDUCE EMBODIED CARBON?

Reduction in the embodied carbon of concrete also leads to saving in cement. This can be achieved by using a two-pronged approach, namely, adopting material efficient designs and also structural efficient designs.

Material Efficient Design

As the RMC and precast concrete sectors mature, the trend of concrete mix optimization, which encourages optimum use of cement, will pick up. The RMC and precast concrete techniques are best equipped to adopt concrete optimization tools. Further, embracing the performance-based specifications for concrete would provide a further boost to the optimization practice. It is well known that the current Indian Standards limit the percentage replacement of OPC by fly ash up to 35% and OPC by GGBS up to 50%. Further, the Indian standard does not permit the 56-day compressive strength criteria for the acceptance of concrete. It is observed that with an intelligent mix design, it is possible to achieve specified strength and durability criteria even with higher than code-specified replacement of OPC by the SCMs. Also, for foundations and substructure located at lower levels need to resist the maximum dead and live loads at a later stage, hence the 56-day acceptance criteria can easily be introduced. The adoption of the use of higher SCM levels and 56-day acceptance criteria can be permitted under performance-based specification, which will a long way in reducing the cement contents in concrete.

The use of digital techniques is growing in different sectors including construction. Digitization techniques in concrete involve the use of sensors and other digital technologies to monitor, track and analyze data. Reports emanating from north America and other advanced countries indicate that artificial intelligence (AI) tools are being developed that use machine learning algorithms to analyze the vast data sets, enabling faster, more accurate and more optimized mix designs. The use of AI-based digitization techniques for mix optimization is presently in its infancy; yet the adoption of wireless sensors to monitor the fresh and hardened properties of concrete (mainly compressive strength) are growing. The latter has made a small beginning in India too. One can visualize a future when the use of AI-based tools would rise in different sectors of industries including the concrete sector. The use of such tools would lead to a greater degree of optimization in the design of concrete mixes, leading to the reduction in the use of cement.

New technologies like 3-D Printing and Ultra High-performance Fiber-Reinforced Concrete (UHPFRC) seem promising. The first demonstration building using 3-D printing was constructed with the initial developmental work done at IIT Madras. Other academic institutions and some private sector companies have also been working on this technology presently.

It is interesting to know that the first precast plant using UHPFRC was set up near Pune and the precast prestressed bridge girders using UHPFRC are being fabricated and used now to replace deteriorated existing girders.

3-D Printing and UHPFRC are indeed promising new technologies for the future. However, it is essential to carry out in-depth work on their life cycle analysis to evaluate how these technologies can reduce the overall carbon footprints of construction.

Efficient Architectural and Structural Design

While the RMC and precast concrete sectors accomplish the task of achieving increased efficiency of concrete mixes, the teams of structural engineers and architects can adopt innovative and efficient designs which have the ability of using lesser amounts of energy-intensive materials like concrete and steel - without of course, sacrificing the safety, robustness, resilience and long-term durability of the structures. For example, the use of hollow core slabs, voided slabs, ribbed slabs, waffle slabs, etc. can minimize the use of energy-intensive materials. Such techniques should be used wherever possible.

There is also a need to reduce the dead loads on structures. For example, in the case of buildings, the use of lightweight partition walls having adequate strength, toughness and thermal and sound insulation would be most welcome as the reduction in the overall vertical loads on buildings would result in reducing the section sizes of structural members which in turn would minimize the use of energy-intensive materials.

Further, wherever possible, the adoption of modular design and industrialized construction can help in fulfilling sustainability-centric design and construction.

CONCLUSION

The decarbonization roadmap of the cement sector in India aligns itself with the Government’s commitment to achieve net-zero emissions by 2070 and the interim target for 2047 in line with the vision of ‘Viksit Bharat’. The roadmap identifies eight decarbonization levers and assigns percentage contribution for each of them to achieve net-zero CO 2 emissions by 2070. The decarbonization levers of clinker efficiency (11.2%) and use of alternative fuels (4.6%) fall in the realm of cement production and the roadmap envisages that these could be achieved initially by increasing the share of biomass and industrial waste as substitutes for fossil fuels and at a later stage by adopting advanced technologies such as green hydrogen, kiln electrification and solar thermal. The roadmap report envisages that CCUS technology would play a significant role (25.1%) from the middle of the current century

The maximum reduction in CO 2 emissions is expected from the decarbonization levers of cement use efficiency (30.2%) and use of SCMs (16.2%). Brief review of the current and future trends in the spheres of concrete, structural engineering and other related fields indicates that the adoption of material efficient and structural efficient designs and optimization and digitization techniques would go a long way in achieving the cement use efficiency goal.

Achieving net zero emissions from the cement and concrete sectors is a gigantic task which can only be achieved with the full-scale participation and support from all stakeholders from the cement and concrete sectors consisting of architects, structural engineers, RMC and precast concrete/plaster producers, builders, contractors and others groups consisting of policymakers, governments, researchers, innovators, customers, etc.

References

- UN Office for Disaster Risk Reduction, The Human Cost of Disasters: An overview of the last 20 years 2000-2019, published 2020, p.30.

- Broken Record :Temperatures hit new highs, yet world fails to cut emissions (again), United Nations Environment Programme (UNEP), ISBN: Job number: DOI: 978-92-807-4098-1 DEW/2589/NA, https://doi.org/10.59117/20.500.11822/43922

- 2022 Global Status Report for Building and Construction, Published by Global Alliance of Building and Construction, United Nations Environment Program, 2022.

- Thomas Czigler, Sebastian Reiter, Patrick Schulze, and Ken Somers, Laying the foundation for zero carbon cement, Report by Mckensey & Company, May 2020.

- “Our Concrete Future” Global Cement & Concrete Association (GCCA), https://gccassociation.org/concretefuture/our-concrete-future/

- Decarbonization Roadmap for the Indian Cement Sector: Net Zero CO 2 by 2070, GCCA-TERI report, March 2025, p.74.

- IEA. 2021. India Energy Outlook 2021. International Energy Agency. Paris, France. https://www.iea.org/reports/india-energy-outlook-2021.

- Technology Vision 2030, TERI

- Greening the Steel Sector in India — Roadmap and Action Plan, Ministry of Steel, September 2024.

- UNEP/Global ABC, Sustainable Building Hub, Collaborative Platform,

https://www.iea.org/reports/india-energy-outlook-2021.